EXERCISES

1. What are the causes and effects of vibrations?

2. Define the terms Time period, Cycle and Frequency in Vibrations?

3. Define, in short, free vibrations, damped vibrations and forced vibrations?

4. Discuss briefly with neat sketches the Longitudinal, Transverse and Torsional free vibrations.

5. Derive an expression for the natural frequency of free transverse and longitudinal vibrations by equilibrium method?

6. Discuss the effect of inertia of the shaft in longitudinal and transverse vibrations.

7. Deduce an expression for the natural frequency of free transverse vibrations for a simply supported shaft carrying uniformly distributed mass of 'm' kg per unit length.

8. Deduce an expression for the natural frequency of free transverse vibrations for a beam fixed at both ends and carrying a uniformly distributed mass of 'm' kg per unit length.

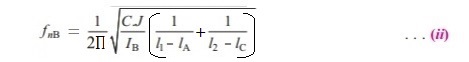

9. Establish an expression for the natural frequency of free transverse vibrations for a simply supported beam carrying a number of point loads, by (a) Energy method; and (b) Dunkerley's method.

10. Explain the term 'whirling speed' or 'critical speed' of a shaft. Prove that the whirling speed for a rotating shaft is the same as the frequency of natural transverse vibration.

11. Derive the differential equation characterizing the motion of an oscillation system subject to viscous damping and no periodic external force. Assuming the solution to the equation, find the frequency of oscillation of the system.

12. Explain the terms 'under damping, critical damping' and 'over damping'

13. Explain the term 'Logarithmic decrement' as applied to damped vibrations

14. Establish an expression for the amplitude of forced vibrations.

15. Explain the term 'dynamic magnifier'.

16. What do you understated by transmissibility?